Propeller Polishing – REPAIRS & CONDITIONING

Propeller Polishing

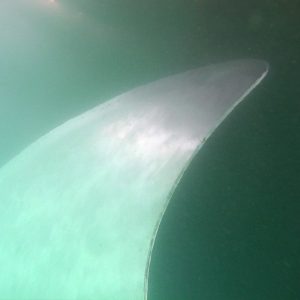

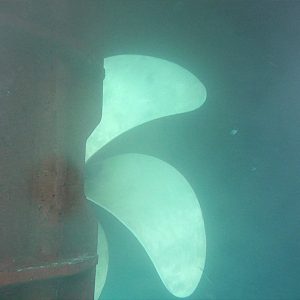

Dubina Engenering use the Scotchbrite 3M system with propeller polish pads in grain 3 and 5 to achieve a high quality mirror like finish (where propeller casting allows). Before and after photos of our underwater polishing service are always provided. Our clients consistently advise us after service of the immediate recognisable fuel savings as a result of our underwater propeller service.

– Before and after photos supplied

– Cavitation evaluation and reporting

– Programmed maintenance

– Aft end inspections (with Photos)

– World class hydraulic underwater polishing equipment

– Immediate fuel cost saving

– Achieve potential fuel savings with programmed underwater polishing of your propeller

Photographic Update of Aft End

Inclusive with programmed underwater propeller polishing, ship owners can view colour photos and report of:

– Propeller

– Rope guard

– Rudder anodes

– Aft end paint condition

– Visual anomalies